EXCEPT AS NOTED, IMAGES ARE FAHIM KASSAM PHOTOS / ALL IMAGES COURTESY OF BOCCI

EXCEPT AS NOTED, IMAGES ARE FAHIM KASSAM PHOTOS / ALL IMAGES COURTESY OF BOCCI

Feature

Happy Accidents

AT THE TOP OF OMER ARBEL’S multi-story studio in Vancouver is an all-purpose space. There are lamps and glass objects packed and ready to ship. Architectural models lie strewn about, not exactly in disarray, but not all that well organized either. Along one wall is an astounding foam construction, originally developed for a museum exhibition. It was ultimately not accepted by the curators, who feared the design would overmatch the artworks they planned to display. And they might have been right to worry, for Arbel’s energies seem uncontainable. Touring that attic space with him this past spring, I felt as if I were paying a visit to his brain. Though he’s an unassuming and approachable fellow, he fairly bursts with ideas, producing objects like a wheel throws off sparks. Were he not up in Vancouver, it’s probable that Arbel would be much better known. But for him, the city has been an ideal support system. Born in Jerusalem, he immigrated to Canada as a teenager, and has lived and worked there since. These days his output is split into several streams. The most conventional is a lighting and glassware company called Bocci, which produces commissioned installations as well as objects for retail. Fabrication is done in Vancouver, entirely by hand, in one of the largest privately operated hot shops anywhere in North America. Since 2015, Arbel has also operated Bocci 79, a showroom and archive, in Berlin, where a wide range of finished objects and prototypes can be seen. Housed in a former 1896 courthouse, this space serves as a test site for new ideas.

64 Beeswax Candle, made of molten beeswax cast in ice, 2017.

Arbel’s other arenas of activity are somewhat harder to pin down. He maintains a discrete architectural practice, and is active in numerous other disciplines under the heading of OAO Works (the acronym stands for Omer Arbel Office). What his myriad undertakings have in common is a way of thinking that is rooted in materials based experimentation. Often, he invents clever “hacks” of existing processes. For example, he has developed a new way of forming concrete, by pouring it gradually into a wooden armature lined with fabric; the result is a spreading, treelike pier with fluted folds. He has created metal objects by electroplating a core artifact (any old bolt will do) several hundred thousand times, allowing the deposit of metal to proliferate into irregular amoebic forms. He has fused glass and copper—which apparently have similar coefficients of expansion—to make vessels in which layers of gleaming mesh are encased within layers of translucent color. Arbel has even made wax candles, using a process adapted from a child’s kitchen craft. He and his team first place a wick into a bucket of broken ice. Hot wax is poured into the bucket; it solidifies within the fissures and around the wick. The ice is allowed to melt, leaving a delicate, baroque form. Though extremely fragile, it can be shipped simply by re-freezing it into a block and putting it on a refrigerated truck.

As if to impose some kind of system on his wildly various creative output, Arbel has always assigned his works numbers rather than titles, in chronological order. He and his team all know them by heart: the wax candle is number 64; the electroplating process is 71; the mixed copper and glass technique is 84. There’s often a discussion in the studio about when an idea is sufficiently developed to get a number—rather like a painter who wonders whether a canvas is finished. This method of keeping track also lends the studio’s projects a scientific air, emphasizing their character as separate (though mutually informative) research initiatives. Perhaps the most fitting aspect of the system, though, is that it’s inexhaustible: it implies a motion toward infinity. This is a quality of many of Arbel’s designs, too. He often works according to a design principle that has been called “mass customization,” in which a potentially endless run of units is nuanced by unpredictable variation. In his on- going Polygon Glassware series (number 31.3), he has worked with the skilled fabricators in a Czech factory to make forms of astonishing thinness in an unusual, vibrant palette. Though there is a common vocabulary of forms to each set, he asked the factory to render them in whatever colors they had left in their batch following the completion of other orders. He then has each set mixed at random, so that no two are alike.

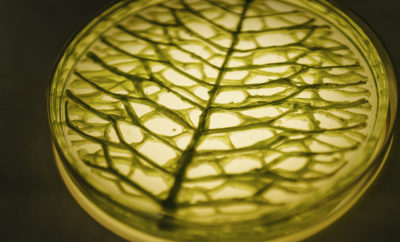

A studio installation shot of the Bocci 76 series, a project in which a vacuum is introduced to layers of hot white and clear glass to pull the white glass through an intervening wire mesh, with electrical components added for light, 2017.

Arbel has employed a similar principle at a much larger scale, too, as in his architectural projects, or installations of lighting or metalwork at sites like the Victoria and Albert and the Barbican Centre—sometimes achieving results that are comparable to the projects of the designer and architect Thomas Heatherwick. Like his celebrated British colleague, Arbel has found ways to infuse making with a restless and generative intelligence. Almost none of the processes he uses involve new technology. Electroplating is two centuries old; any of the glassblowing techniques employed by Bocci could have been achieved in Renaissance Venice; wax casting goes back even further than that. But his handling of these ancient crafts is firmly grounded in the contemporary, by virtue of his embrace of chance operations.

Though the means he employs are assertively analog, Arbel’s sensibility is unmistakably of the digital era. This is evident in the way he leaps from one discipline to another—as if surfing the World Wide Web of human ingenuity—and in the irregular, accumulative nature of his work. In contemporary design, the modernist legacy of functionalism has been scattered to the winds; the field has increasingly departed from problem-solving as its raison d’etre, instead becoming an expressive and individualistic act. Without much fanfare, Arbel has vaulted to the foremost ranks of designers working in this direction. He is more interested in questions than answers, in prototypes rather than products, so he and his team do solve problems, all the time. But they are problems of his own creation.